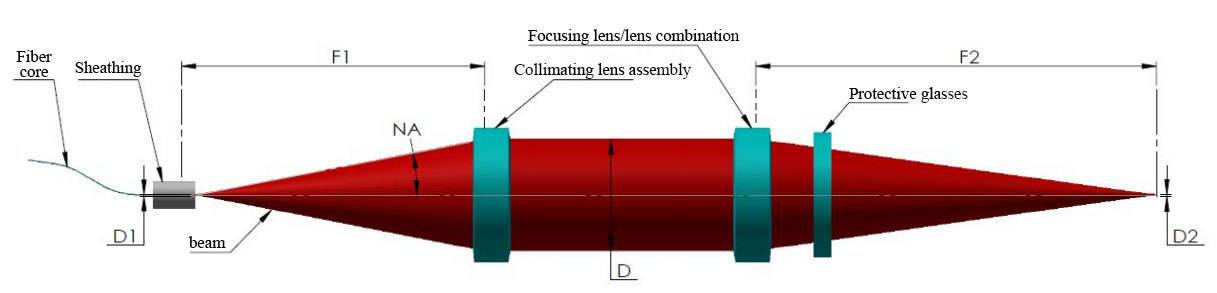

Transmissive Optical Path

Optical Path Design

——

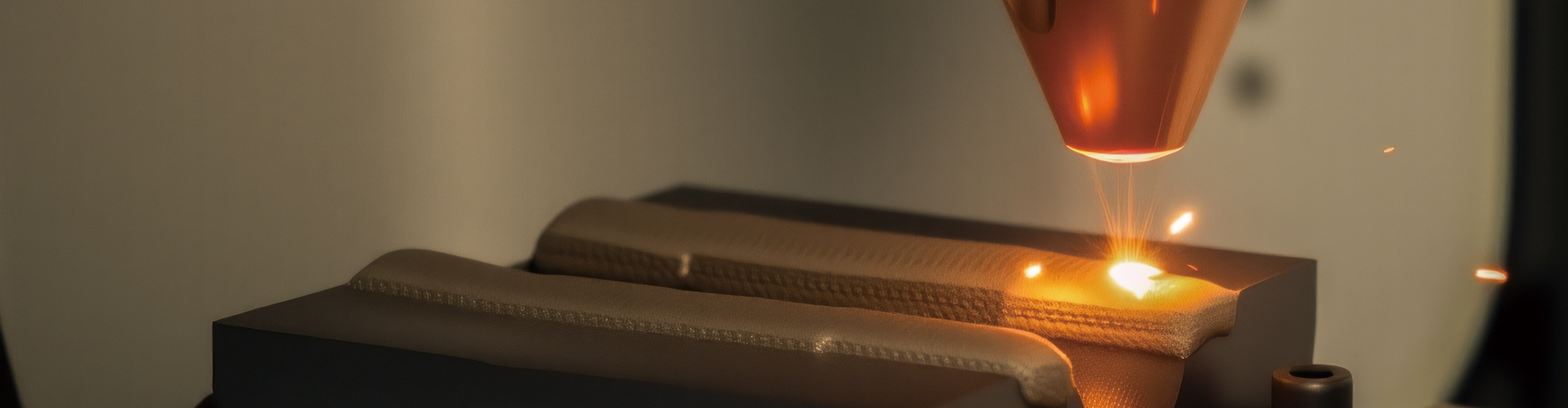

Laser cladding is a process involving the interaction of laser, powder flow, gas flow, and molten pool, where the energy distribution of the laser spot plays a crucial role. Yunding Optoelectronics achieves beam energy distribution from Gaussian/near-Gaussian to flat-top intensity profiles through high-quality optical components, obtaining circular, square, or rectangular spots that meet laser cladding requirements, thereby enabling ultra-high-speed, rapid, and broadband laser cladding processing.

Laser: Fiber laser, semiconductor fiber-coupled laser, disk laser

Basic Components: Double-element combined collimation + single/double-element combined focusing + protective lens, with optional additional protective lens as needed

Typical Applications: Transmissive coaxial annular, transmissive coaxial needle-type, transmissive off-axis

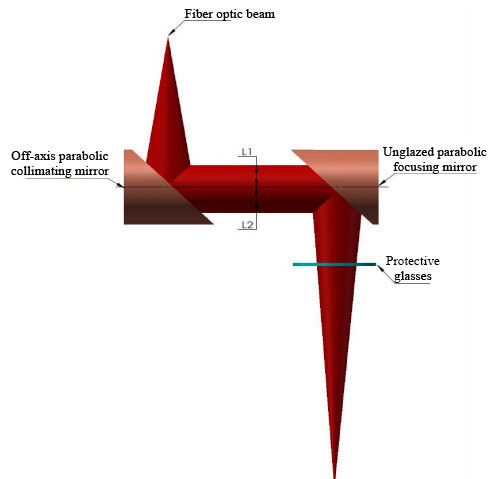

Reflective Optical Path

Laser: Fiber laser, semiconductor fiber-coupled laser, disk laser

Basic Components: Off-axis parabolic mirror collimation + off-axis parabolic mirror focusing + protective lens, with optional additional protective lens as needed; the off-axis parabolic focusing mirror can be replaced by an integrator to obtain a homogenized spot

Typical Applications: Reflective coaxial annular, reflective coaxial needle-type, reflective coaxial broadband, reflective off-axis broadband

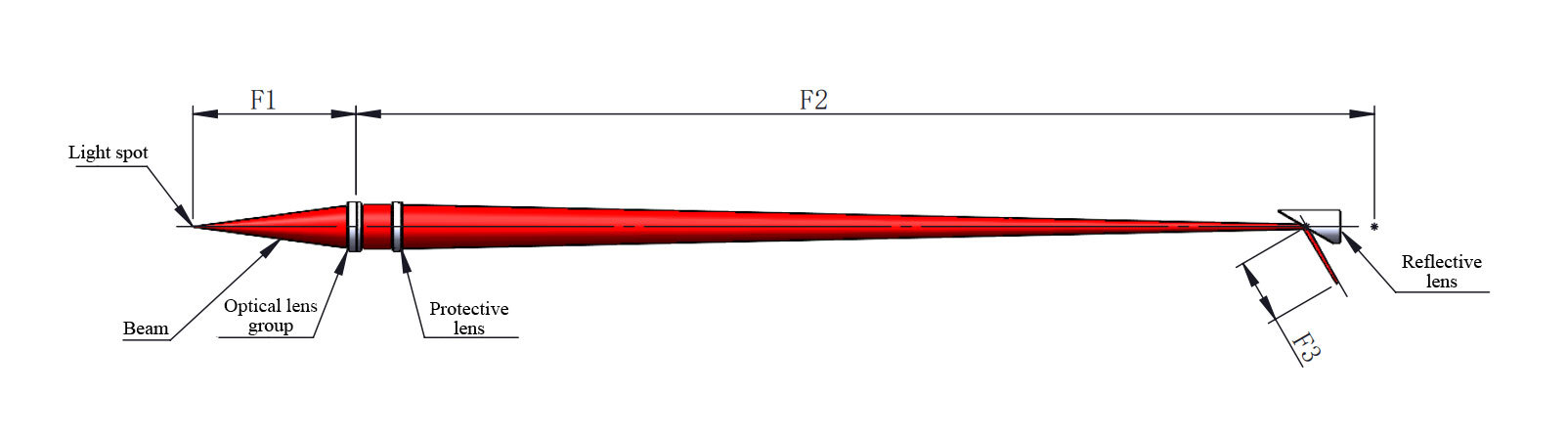

Inner Hole Optical Path

Laser: Fiber laser, semiconductor fiber-coupled laser, disk laser

Basic Components: Collimating lens + off-axis parabolic mirror focusing + protective lens, with optional additional protective lens as needed; the off-axis parabolic focusing mirror can be replaced by an integrator to obtain a homogenized spot

Typical Applications: Inner wall reflective coaxial annular, inner wall reflective coaxial needle-type, inner wall reflective off-axis broadband

High-Quality Optical Components

All laser equipment in our company uses the highest quality optical components worldwide, including focusing mirrors, roof mirrors, integrators, spherical mirrors, protective lenses, etc. The mirrors are manufactured using air-bearing diamond ultra-precision machine tools, achieving nanometer-level control accuracy. Oxygen-free copper (OFHC) is used as the material for mirrors and integrators to achieve high reflectivity and low scattering characteristics. The materials undergo heat treatment to stabilize surface performance, suitable for long-term use. The surfaces of mirrors and integrators are directly milled or turned by air-bearing ultra-precision machine tools, achieving submicron surface accuracy and nanometer-level surface roughness, resulting in outstanding optical efficiency. To enhance the optical properties (reflectivity and polarization performance) and mechanical properties (scratch resistance, corrosion resistance) of the mirrors, all metal mirrors and integrators are vacuum coated.

When laser power reaches tens of kilowatts, the light guiding system experiences thermal load. Our company eliminates thermal load by providing carefully manufactured water coolers (e.g., spiral water coolers installed at the bottom of mirrors). The top and bottom edges of the mirrors are welded together using internal fusion welding technology. Automatic shut-off cooling water connectors facilitate removing the mirrors from laser processing equipment for cleaning, wiping, and maintenance.

Yunding Optoelectronics masters core optical path design and beam shaping technologies, combined with high-quality optical components and high-precision mechanical parts, providing high-quality laser cladding equipment in the industry. Yunding Optoelectronics continuously optimizes these technologies to ensure ongoing iteration and upgrades, promoting technological progress in the laser cladding industry.

Yunding Laser is based on independent innovation, committed to becoming a complete equipment and solution provider for laser cladding/laser additive manufacturing technology in specialized industrial fields.

Contact Us

Address: No.104A, Jinggao Smart Manufacturing Industrial Park , East Section of Gaojing Avenue, Jinghe New City of Xixian New Area , Shaanxi Province

Phone:8615389076596 /8617391725189

Quick Navigation

Message Inquiry

Interpreting Quality with Technology, Building Brand with Integrity

Copyright © 2025 Xi'An Yunding Laser Technology Co., Ltd. All rights reserved