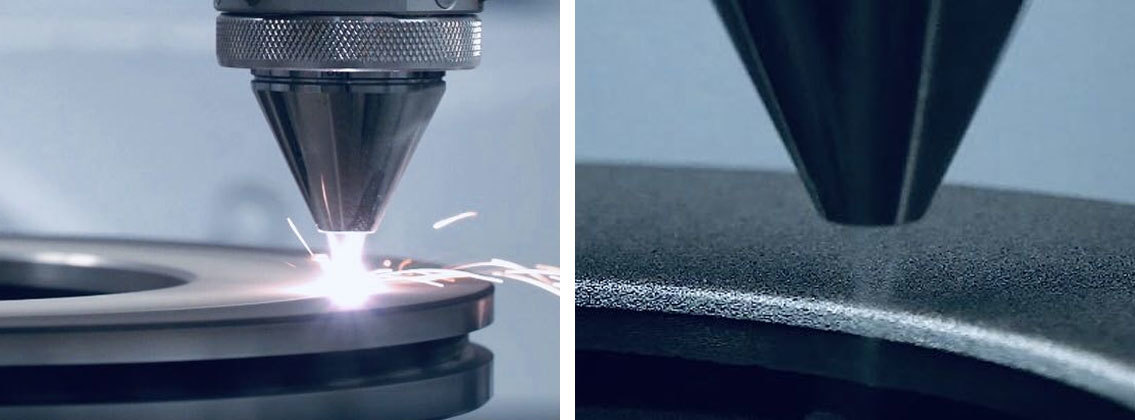

1. Laser Cladding on Brake Disc Surface

Automobile Industry

Automotive Industry

With the development of China's automotive industry, the automotive parts remanufacturing industry requires mature remanufacturing technologies to support it. Laser cladding technology, as an advanced manufacturing process that balances performance and environmental requirements, has shown great potential in the field of automotive parts remanufacturing.

During the vehicle braking process, the particulate emissions generated by the friction between brake pads and brake discs cause significant harm to pedestrians and the environment near emission sources (such as urban intersections). The fundamental solution to this is to improve the wear resistance of brake discs, thereby reducing particulate emissions caused by wear from the source.

Laser cladding technology is mainly used to improve the wear resistance and corrosion resistance of brake discs, while reducing wear particles and harmful emissions generated during braking, thereby enhancing the safety performance of brake discs and extending their service life. It is an important development direction in the automotive manufacturing industry.

2. Laser Cladding on Valve and Valve Seat Surface

In traditional fuel vehicles, valves and valve seats operate under high temperature and high pressure of combustion gases. Additionally, when valves open and close, they impact and rub against the valve seats, causing dry friction between the valve face and seat face, which accelerates valve wear. Some combustion products deposit on the valve face during exhaust, causing corrosion to the valve.

Using laser cladding technology to reinforce valves and valve seats can extend their resistance to high temperature, corrosion, and wear.

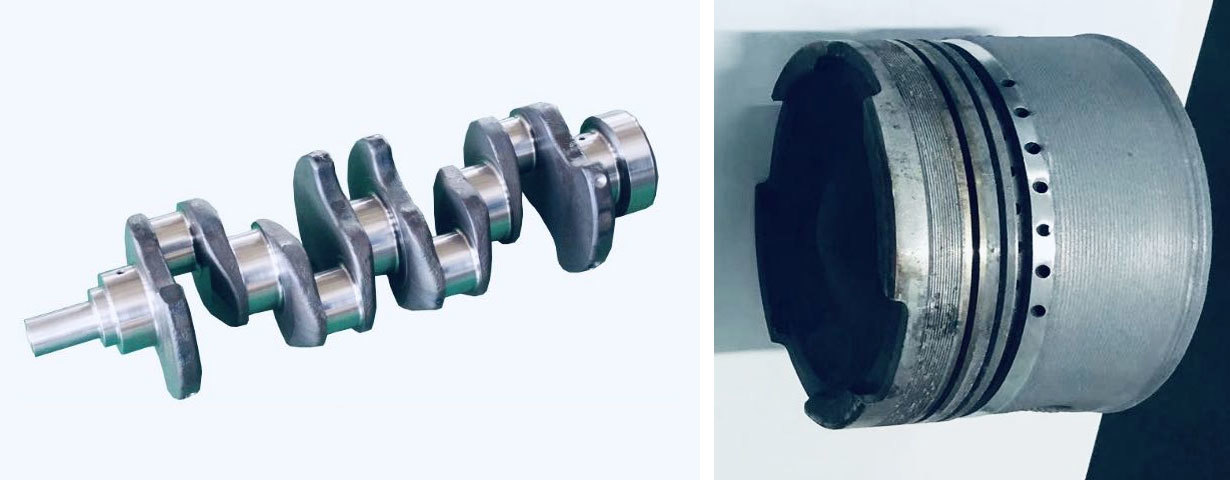

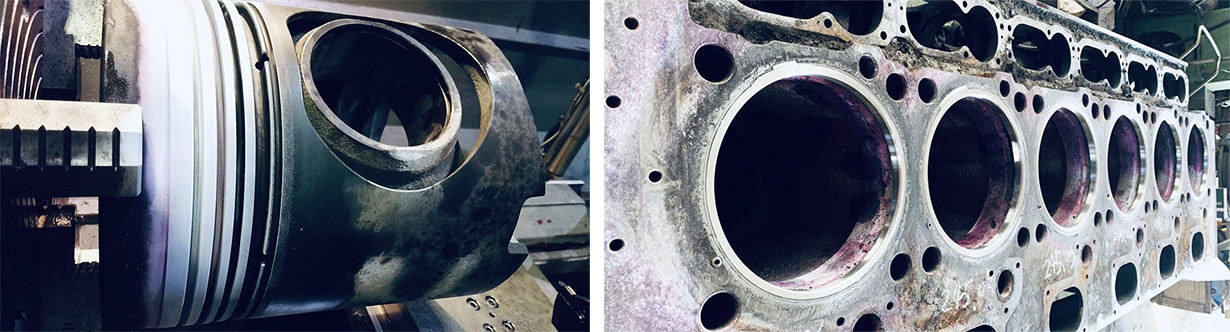

3. Laser Cladding on Crankshaft and Engine Piston

After long-term operation, crankshafts and engine pistons are prone to cracks and excessive wear. Repairing them with laser cladding technology can improve their surface wear resistance and corrosion resistance.

4. Services Provided by Yunding

Outer wall series: Yunding Optoelectronics 6000W, 9000W, 12000W outer wall rapid laser cladding equipment; 6000W inner wall laser cladding equipment;

Motion system structure: four-axis cladding machine tool, manipulator + slide + large rotary table, manipulator + positioner, gantry-type large motion system, etc.

Yunding Laser is based on independent innovation, committed to becoming a complete equipment and solution provider for laser cladding/laser additive manufacturing technology in specialized industrial fields.

Contact Us

Address: No.104A, Jinggao Smart Manufacturing Industrial Park , East Section of Gaojing Avenue, Jinghe New City of Xixian New Area , Shaanxi Province

Phone:8615389076596 /8617391725189

Quick Navigation

Message Inquiry

Interpreting Quality with Technology, Building Brand with Integrity

Copyright © 2025 Xi'An Yunding Laser Technology Co., Ltd. All rights reserved