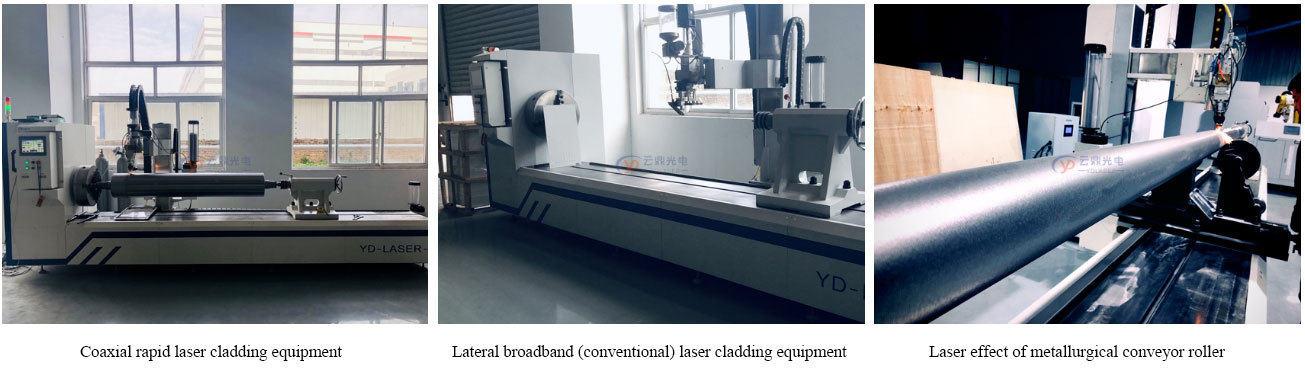

1. Metallurgical Laser Cladding Equipment

Metallurgical Machinery

Metallurgical Machinery

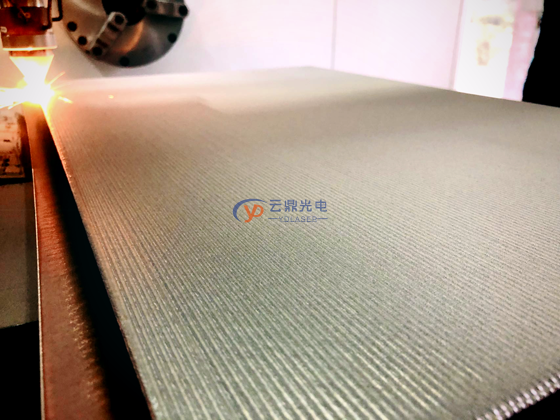

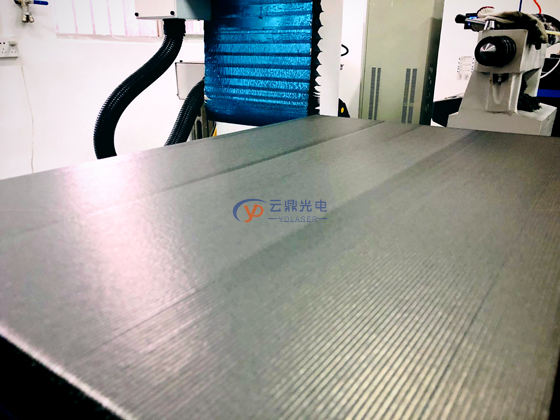

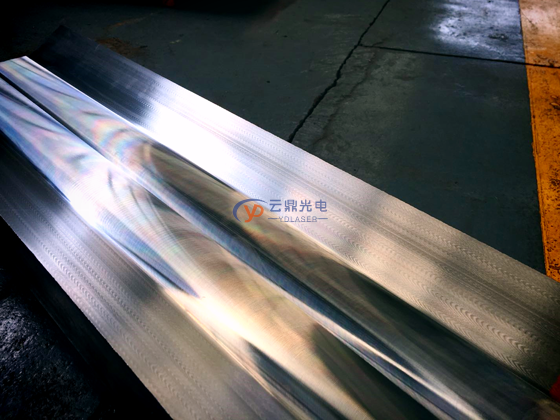

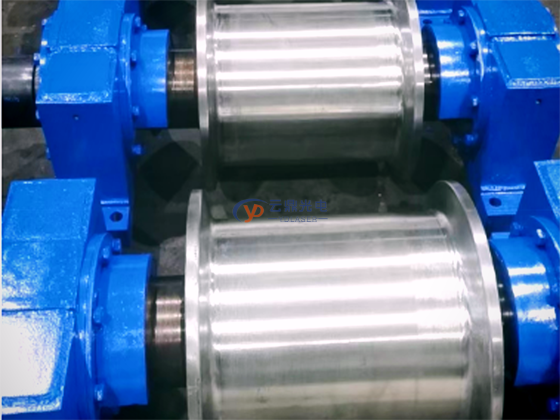

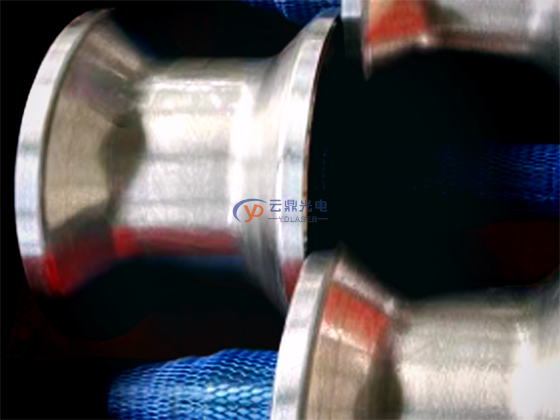

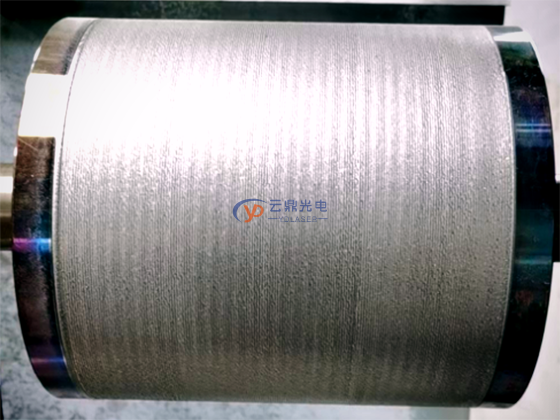

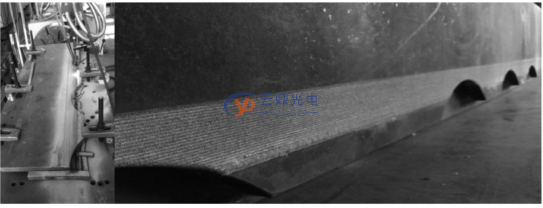

Components in metallurgical machinery on the production line must withstand harsh working conditions such as high temperatures, rolling/sliding friction wear, impact, and thermal fatigue. These components require regular replacement and maintenance. Metallurgical enterprises spend a large amount of funds annually on component replacement and maintenance. Since metallurgical enterprises operate continuous production, laser cladding technology can effectively extend the service life of components and reduce downtime frequency. Currently, this technology is widely applied to products such as laminar rollers, conveyor rollers, furnace bottom rollers, pinch rollers, flat head sleeves, side guide plates, crystallizers, and guide guard plates.

2. Continuous Casting Crystallizer

3. Conveyor Roller Path / Pinch Roller

4. Metallurgical Guide Guard / Side Guide Plate / Arch

5. Yunding Services

Outer Wall Series: Yunding Optoelectronics 6000W, 8000W, 10000W Outer Wall Rapid Laser Cladding Equipment; 12000W Outer Wall Broadband Laser Cladding Equipment

Motion System Structure: Four-axis Cladding Machine Tool, Robot + Slide + Large Rotary Table

Yunding Laser is based on independent innovation, committed to becoming a complete equipment and solution provider for laser cladding/laser additive manufacturing technology in specialized industrial fields.

Contact Us

Address: No.104A, Jinggao Smart Manufacturing Industrial Park , East Section of Gaojing Avenue, Jinghe New City of Xixian New Area , Shaanxi Province

Phone:8615389076596 /8617391725189

Quick Navigation

Message Inquiry

Interpreting Quality with Technology, Building Brand with Integrity

Copyright © 2025 Xi'An Yunding Laser Technology Co., Ltd. All rights reserved