1. Laser cladding of ball valves and valve sealing surfaces

Valve

Valve Industry

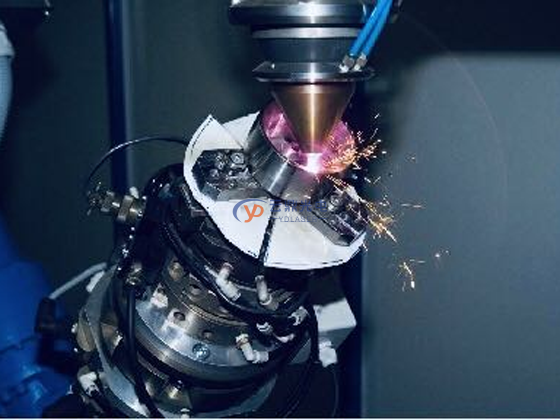

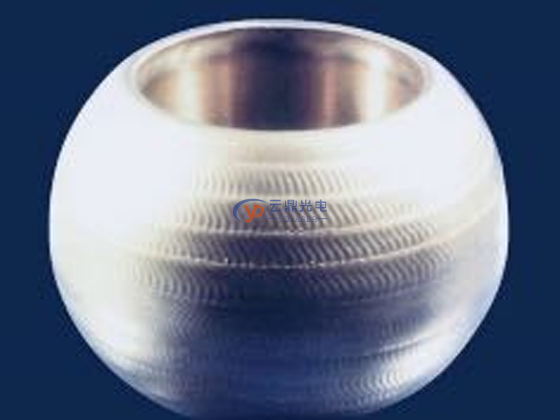

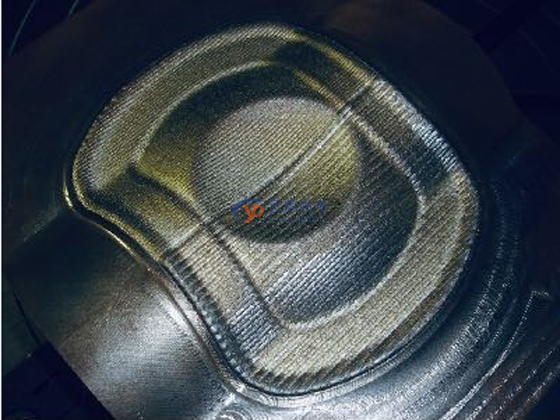

In the valve industry, products such as ball valves, gate valves, and butterfly valves have sealing surfaces that must withstand harsh conditions including high temperature, high pressure, corrosion, and friction wear. The use of laser cladding technology can significantly improve their service life. Compared with traditional processes like PTA, surfacing welding, and spraying, laser cladding features metallurgical bonding, refined grains, low heat-affected zones, shorter process flow, and high efficiency, gradually replacing PTA and surfacing welding processes.

Using laser cladding technology to clad cobalt-based alloys on valve sealing surfaces results in hardness 7-10 HRC higher than PTA and surfacing welding processes, with higher hardness uniformity, lower dilution rate of 15-20%, no porosity, uniform elemental distribution, and a dendritic microstructure. Laser cladding can produce higher quality cobalt-based alloy coatings.

2. Services provided by Yunding

Outer wall series: Yunding Optoelectronics 6000W, 8000W outer wall rapid laser cladding equipment

Motion system structure: specialized machine for sealing surface cladding, manipulator + positioner

Yunding Laser is based on independent innovation, committed to becoming a complete equipment and solution provider for laser cladding/laser additive manufacturing technology in specialized industrial fields.

Contact Us

Address: No.104A, Jinggao Smart Manufacturing Industrial Park , East Section of Gaojing Avenue, Jinghe New City of Xixian New Area , Shaanxi Province

Phone:8615389076596 /8617391725189

Quick Navigation

Message Inquiry

Interpreting Quality with Technology, Building Brand with Integrity

Copyright © 2025 Xi'An Yunding Laser Technology Co., Ltd. All rights reserved