Yunding Optoelectronics High-Power Hydraulic Cylinder Outer Wall Laser Cladding Equipment Fully Upgraded

Yunding Optoelectronics High-Power Hydraulic Cylinder Outer Wall Laser Cladding Equipment Fully Upgraded

Release time:2024-01-31 14:52

The hydraulic support in coal machinery is an important supporting device in comprehensive mining equipment.

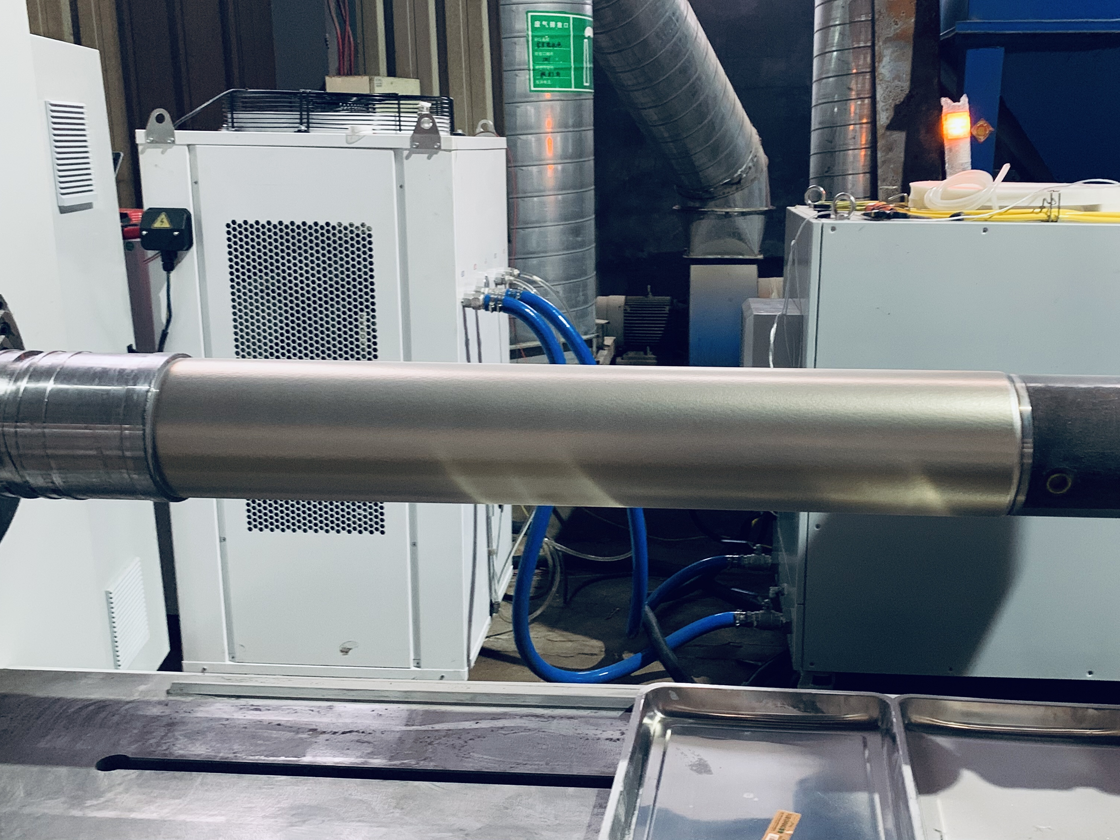

The hydraulic support in coal machinery is an important supporting device in comprehensive mining equipment. The columns, outer cylinders, middle cylinders, piston rods, and side pushes of the hydraulic support are important load-bearing components. They are prone to defects such as rust and scratches due to harsh underground environments like corrosion, wear, and impact, which seriously affect the sealing and service life of the oil cylinder, posing hidden dangers to the safe production of coal mines underground. For new and repaired parts such as columns, middle cylinders, piston rods, and side pushes of hydraulic supports, laser cladding with high-hardness stainless steel technology has been widely adopted to replace traditional electroplating and surfacing processes on the outer surface.

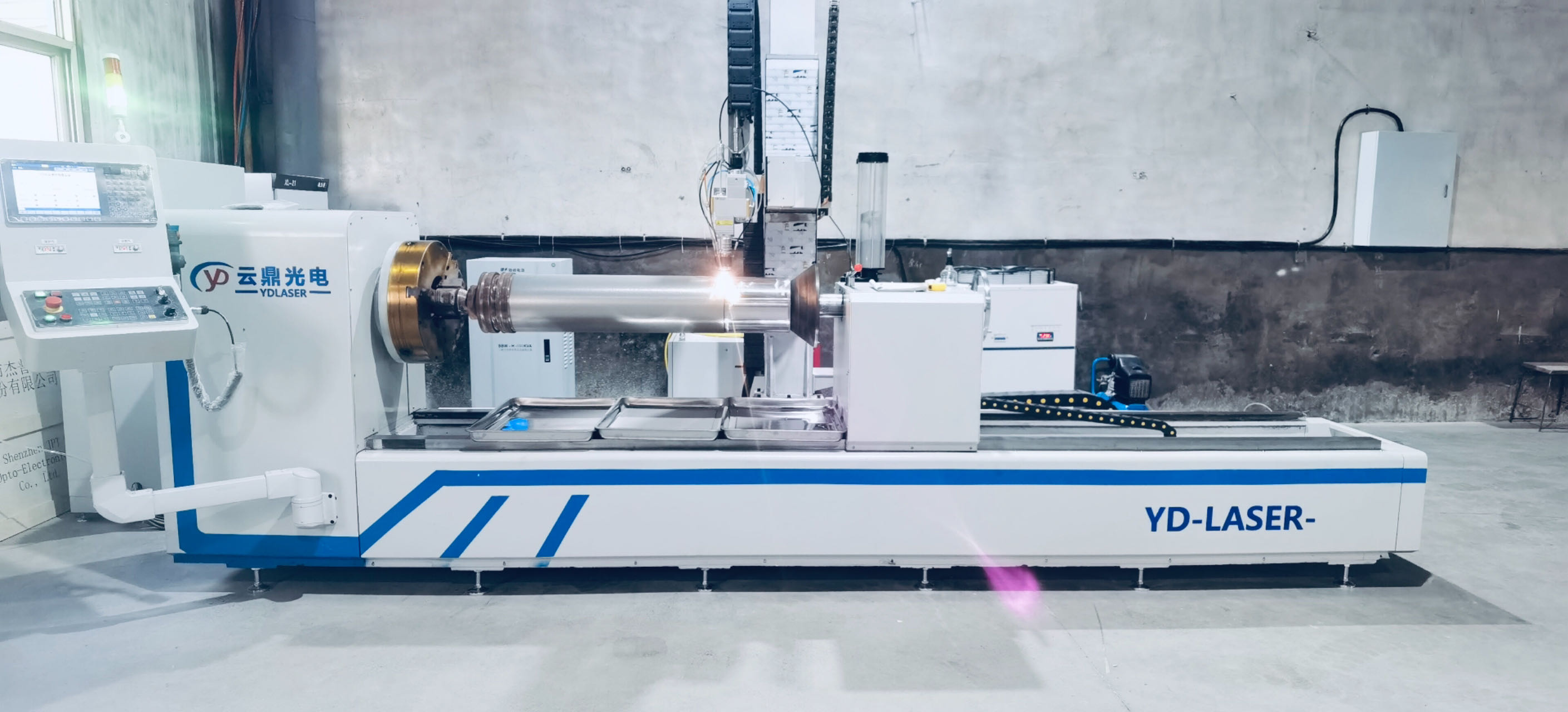

Yunding Optoelectronics' newly upgraded YDGD-9000 and YDGD-12000 high-power laser cladding equipment have recently been mass-launched on the market. The equipment operates stably, with a single unit capacity of over 10㎡/day and a comprehensive powder utilization rate exceeding 93%, significantly improving customers' production efficiency and reducing production costs, helping customers gain efficiency and cost advantages in fierce market competition.

The YDGD-9000 and YDGD-12000 high-power laser cladding equipment use multi-mode fiber lasers. This series of lasers features low attenuation, beam homogenization, and high-reflection resistance. The equipment is equipped with a reflective coaxial annular fast laser cladding head, with core optical components imported from Europe, providing beam integral homogenization. The nozzle structure is optimized, offering better resistance to high temperatures in the molten pool and high reflection. The cladding machine tool adopts a cast bed structure with an electric tailstock. The control system uses a well-known brand CNC system with four-axis linkage, capable of cladding processing for conventional shaft types and simple irregular curved surfaces.

Yunding Optoelectronics' newly upgraded YDGD-9000 and YDGD-12000 equipment feature higher cladding efficiency and more stable cladding performance. We look forward to visits and exchanges with users in the coal machinery equipment industry.

Optoelectronics,Piston Rod

Recommended News

Yunding Laser is based on independent innovation, committed to becoming a complete equipment and solution provider for laser cladding/laser additive manufacturing technology in specialized industrial fields.

Contact Us

Address: No.104A, Jinggao Smart Manufacturing Industrial Park , East Section of Gaojing Avenue, Jinghe New City of Xixian New Area , Shaanxi Province

Phone:8615389076596 /8617391725189

Quick Navigation

Message Inquiry

Interpreting Quality with Technology, Building Brand with Integrity

Copyright © 2025 Xi'An Yunding Laser Technology Co., Ltd. All rights reserved